I stopped by Helimot today and got measured for my new leathers. I’ll be going with a modified ‘Victoria’ style suit with my nickname, sponsorship logos, and the BCR logos across the back and chest. Mike also picked up a new pair of the kevlar F-108’s for passenger work as his bulky Held gloves are about five years old now and held together with gaffers tape. He says the F-108’s are amazingly flexible provide excellent tactile feedback through the thin skin.

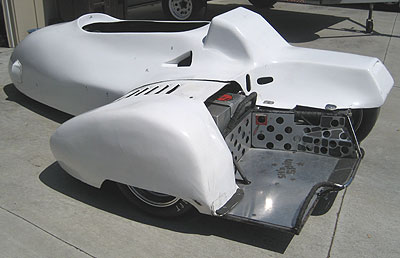

Mike also finished up the heat shield/floorboard for the CSR yesterday. it’s got about five layers of 10oz fiberglass mat on top the base mold he made during the original layup to get the shape. It’s not perfect, but it’d probably stop a bullet. Sanded and painted it looks reasonable, all that remains is to pop rivet the Thermo-Tec heat shielding to the underside to protect it from the heat thrown off by the exhaust headers.