Picked up my suit today, Helmut is an artist. I’m speechless. This is going to look so good at Miller.

~Sarah

Picked up my suit today, Helmut is an artist. I’m speechless. This is going to look so good at Miller.

~Sarah

Just a quick note to say thanks to the Jocelyn and the gang at We all Ride for supplying Mike with a very nice Scorpion EXO 700 for Miller. It’s a shame he’s going to destroy such a goregous helmet. =P

~Sarah

Sunday morning was windy. Mike and I both hate wind. It chaps your lips, makes your eyes and teeth gritty, and dehydrates you faster than you can get water in your system. The only nice thing was that it was overcast, keeping the temps. down in the 80’s and the sun hidden for the time being. Mike borrowed a helmet from Bill Becker and we suited up to go out for first practice. Toward the end of about 12 laps I noticed the sidecar rig start to behave funny, I wasn’t getting the drive out of corners and the engine was spinning up. Mike pounded on the body to let me know to pit, and when we rolled in the hot pit he yelled, “CHANGE PLACES”. He hopped into the cockpit and I jumped on the platform. I should point out at this time that I hate riding on the platform, I do not like that feeling of no control despite Mike saying he has as much control as I do when he’s on the platform. So of course Mike dumps the clutch and lights the rear tire up for about 50 feet getting back out on the track and I’m holding on for my life for two uncontrolled hell laps around the track. What Mike lacks in smoothness and agility with the CSR he makes up for with brute force and binary throttle inputs. I pounded on the body between 3 and 4 to let him know enough was enough and he dropped his speed. We pulled into our pit and he said, “The clutch is slipping.”

If you had read the blog earlier, you’d know that we just made a major change to our clutch before coming out to Reno. We’d installed the Yoyodyne slipper clutch. I asked Mike if he thought the slipper clutch was the problem. He didn’t seem to think that the slipper clutch would eat up a brand new clutch pack that fast. So instead of working on the clutch he went straight for the clutch master cylinder. At this point I’d like to mention the guys at CRG were nice enough to spot us two brand new roll-a-click levers to try out on our stock CBR1000RR master cylinder. Mike had installed the ‘short’ lever Saturday morning and I’d been using it without issue since then. Mike said, “I don’t think this lever fits right, it’s not letting the clutch fully disengage.” He pointed out to a tab on the CRG lever that was hitting the clutch master cylinder. He then pulled off the CRG lever and swapped our stock lever back in place. Mike then did the fastest clutch pack swap I’ve ever seen in my life. I swear to you he had the CSR in the air, the side cover off the engine, the clutch pressure plate off, the ruined pack out, and a new pack in, and everything buttoned up with no mistakes in under 15 minutes.

We made it out for next practice and everything was perfect. I ran about six practice laps to make sure everything was working fine and pulled in to the hot pits. Several of our friends from BARF and the Vampires MC came out to Reno to watch us race, and we’d lined up taxi rides for the more crazy of the group. I needed to save my strength for the race, so Mike hopped in the cockpit of the CSR to take people for some hot laps around the track for the rest of practice. Cygnus, Alicia, Dave, and Planegrey get the hero award for being brave enough to get on the platform with Mike on the throttle of the CSR.

The Sunday race was staged at 2PM, and Mike had a better vantage point than I did, I was too busy racing, so I’ll let him tell the story.

The race came at 2PM, we got in our warm up lap, gridded, and Doug stood on the wall as the starter, he threw the flag and Sarah got the best launch she ever has and we shot right up the inside of 1 with the pack, Gary Wolf from Portland nearly trading paint with us as he fought for the line, Sarah had me in the gravel to stay in the groove and on the power. For the next four laps she ripped around the track holding a solid 7th position with Leon behind us on a F2, and Redneck Racing tucked behind Leon.

I was on the back making myself as wide as possible in the lefthanders to try and keep Leon from even thinking about going by when it would look like he’d think about passing. After three more hard laps holding off Leon Sarah started to fade. I could feel her cornerspeed start to go off and the rig drifting out of the exits which ment she was starting to lose upper body strength. Leon closed on us out of 5, got by, and Redneck Racing used it as a slingshot to make a move on the both of us as we rolled out onto the front straight jumping from 9th to 7th.

We were back in 9th and now chasing Leon for all we were worth. I knew Sarah was tired, but I was still screaming in my helmet “GET HIM GET HIM” and leaning as far out and forward as I physically could to get the weight down on that front wheel so she wouldn’t have to put so much effort into getting the CSR turned in. A couple laps later with Sarah trying her best to chase down Leon and grab another position we took a respectable 9th place out of 12.

This weekend, Sarah learned how to go fast.

We had an excellent weekend all things considered. Given the mechanical issues, Mike’s minor mishap, the crummy weather, and other little gremlins we still had a great three days of racing with some of the most professional roadracers you’ll ever meet, and we still placed in the top 10 both races. I’ll take the 9th place finish today, no problem there. Bill Becker and his son finished first, Dave and Jamie took second, and Mark/Bobette snagged another third. Our 8th and 9th place finish bumps me up to 7th in the Driver standings, and Mike to 6th in the Passenger points. Next stop is Miller Motorsports, and we will kick ass out there.

~Sarah

Reno was crazy, stressful, hot, and fun. Mike picked me up Thursday after work and we headed straight to the track without incident. We dropped everything off at the track around 10PM and got back to the hotel after doing some late night grocery shopping to eat some dinner and collapse into bed.

Friday morning we got back to the track around 8AM and started prepping for practice. Mike and I lifted the body off the CSR and the first thing Mike notices is that the rear body pin has snapped off of it’s mounting plate in the body during the drive out and is still sitting in the body mount on the rig. Mike screamed, yelled, and swore for a few minutes. Something he tends to do when unexpected things like this happen. Once he had settled his nerves we ran back into town to the hardware store and picked up a carriage bolt, an aircraft nut, and a couple nylon fender washers. Back at the track Mike drilled straight through the steel mounting plate fiberglassed into the body and was able to drop the carriage bolt exactly where the body pin used to set. Everything was secured with the nylon washerrs and aircraft nut, and Mike epoxied the rubber body bumper cone back to the body. With some minor adjustments and the surgical application of a sponsorship sticker over the head of the carriage bolt on the outside of the body you would never know anything was any different.

Practice went well and I started to really pick up speed on the short configuration 7 turn 1.2 mile track. It was mostly high speed lefts with one fast turn three right, and a right hand chicane kink between the gravity bowl and turn seven that you could practically draw a straight line through. Our Translogic snapped an Allen bolt on the bottom of the bellcrank, and Mike had to swear at it a bit and fit a new Allen bolt. He then proceeded to re-assemble things in the wrong order which caused him to panic a bit as he thought the shifter had failed or maybe we’d bent a shift fork, when in reality he’d mounted the top of the Translogic one mounting point too high.

Sometimes, it’s the simple things.

The race was staged at 2PM and we went out for our warm-up lap. I was gridded mid-pack left right behind Bill Becker with Roy Janes behind me. The flag dropped and I didn’t have the bike in gear, so I had to slam it into second and light up the rear for the dash into turn 1. This allowed Roy to pass me on the outside during the start. I was able to stay right with Roy for the next five laps, trying to determine where I could set him up to make my pass. I was faster down the front straight than he was, and I could carry more speed through 1, 2, and into 3 than he could. But he would pull away into the gravity bowl. On the exit I could see that he was pushing the front badly and had to reduce his exit speed. The CSR had no such issues and I could reel him in every time on the exit of the gravity bowl into the chicane. While trying to get around Roy Sean passed us both. Down the front straight we got the white flag and I was determined to get both positions back. I started my drive to get by Roy and Sean, pushing the CSR as hard as I could through 3 and into the gravity bowl high so I could turn down as late as possible and get WFO to draw a striaght line through the chicane and carry high corner speed into 7 to beat them on the brakes on the inside of 7 or get them with brute force on the front straight. I dove into 7 with more speed than I’d carried all day and got on the throttle hard, the CSR pitched out sideways under power as the rear wheel lit up, I corrected, it pitched back left, hooked up, and I pinned it and shot for the checkered flag in 8th position, my hopes of making a move on Roy and Sean shot with that mistake.

It was then I noticed that the chair felt ‘bouncy’ and I looked back to see that Mike was gone. I got hard on the brakes and tiptoed around 1 and 2 gently, and looked over towards 7 once I was headed back towards 3 to see Mike walking along the edge of the track with his hands up in the air.

I’ll let Mike describe things from his point of view.

Driving out of the last corner on the last lap onto the front straight Sarah lit up the rear tire but good and the rig stepped out a good three feet. I didn’t have my weight in the right place at the right time, and I was using a new grip for left hand corners. Next thing I knew I was asphalt surfing at 100mph and Sarah was heading for the checkers without me.

I just tucked my arms in the old cross-your-heart fashion and proceeded to do breakdancing flairs down the track till things came to a full stop. I popped up, made sure nobody was coming down the track at me, and then started walking down the side of the track with my thumb out. Luckly Redneck Racing gave me a ride in.

Here’s the damage to the gear… Lost my buttpuck, luckly I have a spare puck. My helmet is toast, the Helimot F108’s held up good.

Mike was uninjured, not so much as a scratch. I think he’s just developed a talent for crashing after all these years. Our finish was ruled a ‘mulligan’ since it was the last corner of the last lap and I gained no tactical advantage by unloading 200 pounds of excess baggage before going WFO for the checkered flag. I’m sure if I’d actually caught and passed Roy or Sean without Mike on the back there would have been an issue. I’ll take the 8th place, I’m just glad I noticed Mike was missing before cranking it over into turn 1. I could have flipped the CSR if I didn’t notice he was missing. It was an exciting day with Frank and Dennis getting the win, followed by Wade and Xtine, and Mark/Bobette rounding out third.

~Sarah

The CSR is fully prepped and in fighting trim. We were up late last night getting all our gear organized and packed for the drive out today. We’ll leave Santa Cruz around noonish and hopefully arrive at the track some time late this evening to drop off the trailer and check into our motel room.

Thanks go out to Scott at Blanco Basura for cutting us some last minute decals, Joe at Constructors Racing Group (CRG) for the levers, Bill at Pacific Media Blasting for the excellent work on the suspension components, John Sloane and the team at Eastwood for the excellent technical expertise, and Fred at Yoyodyne for the slipper clutch.

Without your support, our dream of being the best Superside America team in the Nation wouldn’t be coming true.

~Sarah

Mike went psycho on the CSR last night. All the rims came off so the bearings can be inspected in the hubs and carriers. Axles need to be inspected. He pulled the front swingarm and leading link fork, the rear swingarm, and the outside spindle and caliper carrier. These go to our media blaster / metallurgical expert today to get stripped down and then inspected for stress fractures or weak points. Then it’s back here where they will get shot, cured, and freshly packed bearings will be reinstalled and everything reassembled and safety wired again. Mike feels there have been too many ‘incidents’ this season due to mechanical failures. He states that he was a complete nut about keeping his bike tidy when racing with the AFM, and never once had something fail, which is why he always says to me, “Better to catch something small here in the garage, than to be suprised by something big out on the track.”

Rig looks funny with all the suspension components stripped off of it, Mike assures me it will be back in fighting trim in a couple days.

And when it’s all stripped off, there is not exactly much in the way of suspension parts sitting there. There is some light surface rust buildup on areas of the parts, so I can see why Mike wants them stripped and inspected.

Blanco Basura is supposed to come by in the next evening or two and work with us on the new sponsorship design skin for the rig. No idea what they have in mind for version two, but they crank out amazing stuff. We have a couple new sponsors to incorporate into the new skin, so we’re happy that we’ll have it done in time for Reno-Fernley so we can fly their corporate logos around the track for the photographers and fans. Less than ten days out from raceday at this point!

~Sarah

Yoyodyne Slipper clutch.

So easy to install even a driver could do it.

So with Mike providing pointers and handling anything that needed a serious amount of brute force to tackle, I installed the slipper clutch in the CBR1000RR engine that powers our CSR. It was rather simple.

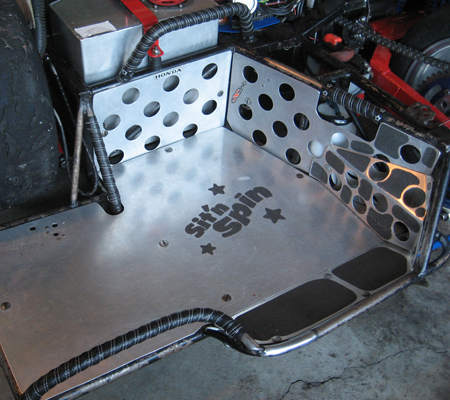

First things first. Oil needs to be changed before the next race, so out comes the bolt on the deep sump pan and three quarts of ‘still looks good to me’ Repsol 4t hits the bucket. Fourteeen 8mm hex head bolts later and a couple taps with a rubber mallet and you’re greeted with this sight.

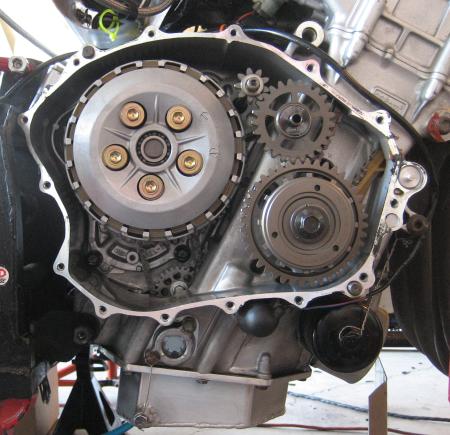

Remove the five 10mm hex head bolts holding on the clutch springs, the outer pressure plate, grab your dental picks and slide out the clutch plates out keeping them in order, the two spacer rings at the base of the basket paying close attention to their orientation, and put a huge amount (Mike comes in at this point) of force on the 12 point 30mm clutch hub nut to break it loose. Most of the normal world would need to run out and buy a 12 point 30mm socket. With Mike it’s, “What color would you like that in, my Dear?” Once the nut is off, remove the two washers, slide the clutch hub off, and the big flat washer always sticks to the back, slide it off and set it with the other two washers. Once that is done you can pop the clutch basket off by sliding the upper starter drive gear out of it’s race and turning the basket sideways. Mike says this is a great time to inspect the needle bearings and associated clutch hardware. You’re greeted with this sight when you’ve done all the above.

And check this out, this is so cool! You can see the crank and a connecting rod through a big clearance window into the crankcase. That chain coming off the transmission input shaft drives the oil pump.

Once everything is given the ok, I reinstalled the clutch basket making sure that it was fully meshed and flush with the output gear on the crank. Then I popped on the big flat washer, and slid on the new Yoyodyne slipper clutch hub. Once that was in place and I was happy it was flush and turning freely without binding I replaced the two outer washers and put some blue LocTite on the clutch hub nut and cinched it down. At that point Mike jumped back in with a four foot long torque wrench, and per the instructions threw an ‘assload of newtonmeters‘ on the clutch hub nut.

Once he was done grunting and showing the clutch hub nut who the alpha male in the room was, I unpacked our new Barnett (thanks Jocelyn!/We all Ride) complete clutch pack kit. This is simple, standard friction first, metal plate THEN the narrow friction ring and the two OEM judder rings from the original clutch pack that ride on the inside diameter of the thin friction ring (standard order on a stock CBR1000RR clutch pack is narrow friction ring/judder rings, metal plate, standard friction, and so on) then metal, friction, metal, friction, lather, rinse, repeat. Till you get to the outside of the clutch pack where you top it off with one final thin friction ring. Then the pressure plate goes on, and the new springs go in place held in with their keepers. Mike told me to NEVER use any kind of LocTite on the allen head bolts that hold the springs on a clutch pack in place. He says he did this once and ended up snapping a post off the clutch hub trying to get the LocTite’ed bolt out. Anyway, the pressure of the springs alone is more than enough to keep the bolts in place as long as you bottom them out and cinch them down snug.

And this is what you have when you’re all done. A sexy Yoyodyne slipper clutch ready for action at Reno-Fernley Raceway on August 17th, 18th, and 19th.

While I was installing things Mike went psycho-OCD and polished all the 8mm hex-head bolts that hold on the right side engine case. A little three-bond around the outer edge after wiping the mating surfaces down with some brake cleaner and things just slide back together. I went through with the small torque wrench and cinched everything down to the ‘click’. We then put the drain plug back in, safety wired it, and filled the engine with three fresh quarts of Repsol 4t. And that’s it, a lazy afternoon of work to install a product that should really help me out on the track.

~Sarah

So Mike picked up an industrial electrical convection oven off of Craigslist a bit back from a guy who worked at Stanford Labs. The price was right at 90 bucks as Mike had been pricing out powdercoating ovens and even the cheap knock off units with a decent amount of space inside were starting at under 400 bucks.

The biggest problem was the guy from Stanford Labs was no EE. The wiring was Jerry-rigged to put it lightly. Mike made a trip down to the electrical supply store and bought a few inexpensive components and a couple hours later he had a fully functional shop oven in the garage. Which means he can quit using the oven in the kitchen for shop work or I’m going to kick his ass.

This goes with the Eastwood ‘Elite’ powdercoating kit we picked up. Mike hates to paint. Of all the things Mike can do, weld, fabricate, machine, lay up fiberglass, CAD and Solidworks, paint is his blind spot. It is a black art to him and he’s never been able to master it properly. He says it’s mostly because he hates the chemicals and all the mess, I have to side with him because I hate the way he smells for the next several days after he’s been working with the chemicals. In comes the powdercoating kit. Mike did a couple months of research and determined that he had enough aptitude to prep parts and lay powder without issue, and that with the addition of an oven of some sort and the powdercoating rig we could at least get started. Mike’s trying to convince me he needs a sandblasting cabinet, I think he’s lazy.

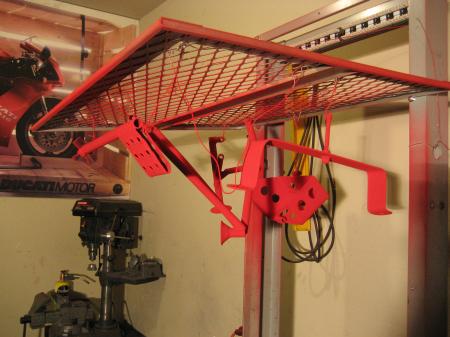

We pulled the main body mounts, gas tank strap, battery box, and brake pedal off the F1 to use as our starter parts. Mike stripped these down with paint remover then carefully cleaned every surface of the components with various types of wire wheels and cups chocked up in the drill press. The parts were then pre-heated in the oven, allowed to cool, and then wiped down with PRE and wired to the oven rack.

Then we just hooked up the HotCoat gun to the compressor, plugged it in, and started puff, puff, puffing the powder on the parts. Here’s a couple shots of the fresh powder on the parts before we popped them in the oven to bake.

Then the parts baked in the oven for about 30 minutes till the powder ‘flowed’ out. Once that happened Mike gave the parts another 20 minutes of bake to cure the powdercoat and shut off the oven. Here’s a shot of the cooling parts a couple hours after the 20 minute cure.

And this morning we mounted up the components after we cleaned up all the fasteners on the wire wheel in the drill press. For our first parts for the F1 rig out of the HotCoat system I have to say I’m really impressed. Mike is blown away with the quality and swears he will never ever paint another metal component again. He’s already ordered some high-temp powder so he can shoot our exhaust and some low-temp powder so he can shoot our aluminum structural components.

If you were able to handle using the EZ-Bake oven when you were five years old and turn out those little cornbread muffins, you could easily turn out professional grade powdercoated parts in about three hours from ‘unbolt’ to ‘bolt it back on’ with a little practice. Now if you could only powdercoat fiberglass.

~Sarah