100,000 psi. induction hardened custom turned hotness. Bent axles are now a thing of the past.

Thanks Jake, Argon Hydraulic Service in San Leandro f’n rules.

100,000 psi. induction hardened custom turned hotness. Bent axles are now a thing of the past.

Thanks Jake, Argon Hydraulic Service in San Leandro f’n rules.

Mr. McFeely just dropped off the R45’s. Thanks for the hookup, Bill.

Doesn’t look like nearly 800 bucks when it’s sitting there. I’ll have these on the rims and balanced up this weekend.

Sarah and I are both out running around as fast as we can trying to get our sponsorship in order all while trying to maintain some sembelence of a normal life outside of all pre-race-season prep madness that turns into a whirlwind of actvitiy. Just today we witnessed a sample of that along our gauntlet across the East Side to run some errands.

On the way back from OSH we decided to take Soquel Ave. home to avoid tourist traffic on Hwy 1. I decided to stop by Drew’s Used Tools on the way back. Seeing that Drew was engaged in a phone call, Sarah and I decided to step into the showroom and oooh and aaaah at some of the more expensive hardware I’ve not lied to myself enough yet to justify purchasing for my small workshop.

We chat with Drew about racing, how Sarah’s the only female Formual 1 Superside America racer. How she doesn’t finish last, or even near last, and how we’re looking for sponsors. An idea is born, a few details are exchanged… and now Drew will have his shop logo on the side of a F1 rig running the national circuit.

And now we have a tool sponsorship, sometimes things just work. We like having Santa Cruz sponsors.

http://www.merchantcircle.com/business/Drews.Used.Tools.831-477-2883

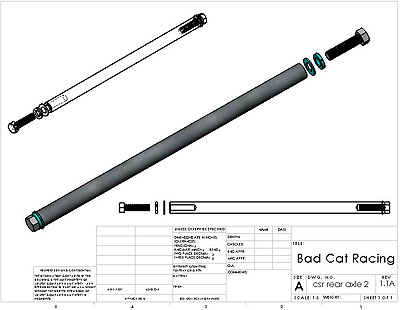

So the rear axle on the CSR is bent. I just happened to notice this when I was swapping out the tires for the last race of the season and put the axle on some glass to see if it was true. It’s a very slight bend, but enough of a bend that I’d like a new one machined out of something resembling a real alloy. I’m thinking 4140 HR steel and having them heat treated post maching but not to the point of being brittle. Here’s the existing axle reflecting on a glass tabletop, the bend is pretty obvious when viewed in this manner, it’s really only about a 64th of an inch.

Fooling around in Solidworks I came up with machining diagrams along with proper fastners and sent them over to Nichols Mfg. in Milpitas for a quote. I’m still waiting to hear back on that. Hopefully they’ll be able to turn it around in a reasonable amount of time.

Also modeling a new rear brake caliper mount that will allow me to get the caliper off the rotor without removing the rotor from the hub. Which will be great… because the rotor is held on by no less than 10 hex head bolts.