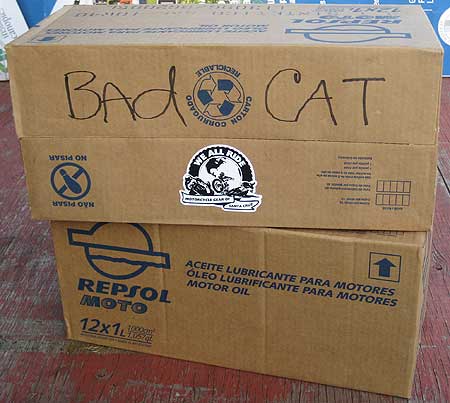

Joaquin w/Repsol dropped off the cases of oil today for the rig. Pouring the oil in the engine was the very last thing that needed to be done to finish the prep of the CSR. Thanks Joaquin, THANK YOU REPSOL! And thank you Jocelyn and the crew at We All Ride! All of you make my season possible.

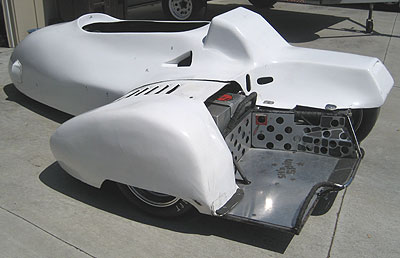

Mike got the rig up to operating temprature after that to cycle in the new plugs and oil. He checked the coolant levels with the engine hot, bupred the extra air out of the system, and then safety wired the radiator cap shut. Stick a fork in it, it’s done. Blanco Basura stopped by and finished up the decals, and now the F1 looks professional, almost like we actually know what we’re doing. Blanco worked their asses off into the night getting the vinyl cut for the rig, and we can never thank them enough. I hope I pull a good finish Saturday and Sunday to make you proud!

~Sarah