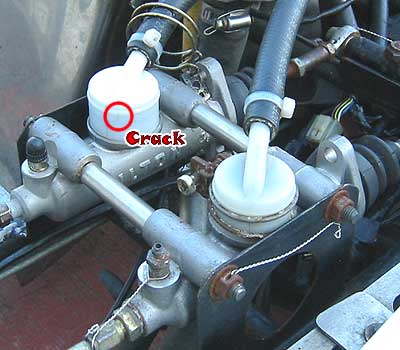

So I noticed brake fluid leaking from one of the Tilton master cylinder literally after I’d cinched the last tiedown on the CSR the afternoon before we left for Reno/Fernley. It turned out that one of the nylon remote reservoir feed caps on the master cylinder had decided that would be an excellent time to develop a crack and start pissing fluid. Better there in the driveway than halfway around the track I guess. As I found out, this isn’t a part Winchester Auto or Kragen just have laying around. And it’s not a part you can fix with JB weld and epoxy no matter how hard you cross your fingers. After much panic I discovered that the nylon reservoir on the RGM was exactly the same size as the one on the CSR. So the RGM was cannabilized and the brakes on the CSR bled in the dark the night before we left for Reno with the rig strapped to the trailer.

Now that things have calmed down I figured I’d pick up replacement cap and a spare for the toolbox. Tilton as it turns out does not sell direct, but they’re happy to give you a list of resellers in the middle of assfuck-nowhere who do. So I place a call to the closest guy in the interest of shipping charges. He takes his sweet time calling me back only to tell me it’s a ‘special order’ part, and to top it off it’s 10 bucks a pop, and there will be shipping to boot.

Yeah, let me get back to you on that…

So I jump on Ebay, and sure enough, there is exactly what I need for Three Dollars and Seventy-Five Cents New in the Box. I bought two.

http://cgi.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewItem&item=270015006879