Today’s update… lots of pictures.

I disassembled all the components last night as I was happy with how the final assembly was functioning.

After cleaning all the braised joints up on the parts and frame with a wire wheel I laid down a couple coats of high temp chip resistant epoxy paint. I also took this chance to clean up all the old fastners on the wire wheel to make them sparkle.

When I got home today I threw the smaller painted parts in the oven on 200 for 20 minutes to bake on the paint. The fresh paint on the frame was given similar treatment with my heat gun for about 20 minutes then cooled down with my air compressor.

Here’s how the bellcrank and spacers turned out after paint.

And here’s the bellcrank with the bearings pressed in place.

And here’s the bellcrank and spacers mounted up in place with the new hardware. Lots of last years gunk to clean off the engine and frame yet before race season.

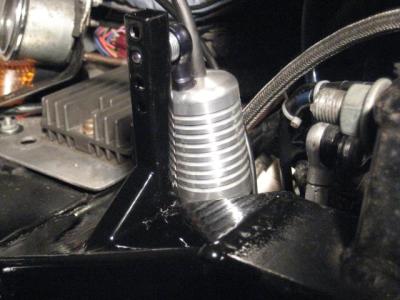

Here’s how the top mount for the translogic turned out once I’d cleaned up the braised joints and painted the frame. Shame is now I have a shiny clean spot on my battle worn frame.

First impressions: It’s very light. I’d say a pound at the most. The outer case is all spun aluminum. I resisted temptation to open it up and see how the guts worked.

It’s considerably lighter than the linkages, old bellcrank, and toebox shifter assembly that were removed. So I guess that means I can have that extra slice of bacon with breakfast.

From my playing with it, if the engine is running… it -always- changes gears, no matter what. I’ve yet to be able to get it to false neutral or miss a shift so far with bench testing. But that proves nothing, we won’t know for sure till we get it out on some asphalt and I can dial it in with some load on the transmission.

If the engine isn’t running it will still shift, but you gotta wiggle the countershaft sprocket a bit to get the transmission to pop into the next gear before it will shift again.

But, if the engine is off, it will go from neutral to first, or from neutral to second… and back to netural from either engaged gear flawlessly with just a dab of the button. That alone beats the hell out of crawling headfirst into the F1 body to try and wiggle the toebox shifter with my hand to get the bike into neutral to move it, or into gear to keep it parked.

I can understand why the system costs nearly 1400 bucks.