So Mike picked up an industrial electrical convection oven off of Craigslist a bit back from a guy who worked at Stanford Labs. The price was right at 90 bucks as Mike had been pricing out powdercoating ovens and even the cheap knock off units with a decent amount of space inside were starting at under 400 bucks.

The biggest problem was the guy from Stanford Labs was no EE. The wiring was Jerry-rigged to put it lightly. Mike made a trip down to the electrical supply store and bought a few inexpensive components and a couple hours later he had a fully functional shop oven in the garage. Which means he can quit using the oven in the kitchen for shop work or I’m going to kick his ass.

This goes with the Eastwood ‘Elite’ powdercoating kit we picked up. Mike hates to paint. Of all the things Mike can do, weld, fabricate, machine, lay up fiberglass, CAD and Solidworks, paint is his blind spot. It is a black art to him and he’s never been able to master it properly. He says it’s mostly because he hates the chemicals and all the mess, I have to side with him because I hate the way he smells for the next several days after he’s been working with the chemicals. In comes the powdercoating kit. Mike did a couple months of research and determined that he had enough aptitude to prep parts and lay powder without issue, and that with the addition of an oven of some sort and the powdercoating rig we could at least get started. Mike’s trying to convince me he needs a sandblasting cabinet, I think he’s lazy.

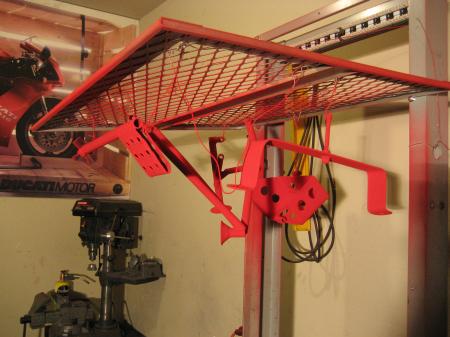

We pulled the main body mounts, gas tank strap, battery box, and brake pedal off the F1 to use as our starter parts. Mike stripped these down with paint remover then carefully cleaned every surface of the components with various types of wire wheels and cups chocked up in the drill press. The parts were then pre-heated in the oven, allowed to cool, and then wiped down with PRE and wired to the oven rack.

Then we just hooked up the HotCoat gun to the compressor, plugged it in, and started puff, puff, puffing the powder on the parts. Here’s a couple shots of the fresh powder on the parts before we popped them in the oven to bake.

Then the parts baked in the oven for about 30 minutes till the powder ‘flowed’ out. Once that happened Mike gave the parts another 20 minutes of bake to cure the powdercoat and shut off the oven. Here’s a shot of the cooling parts a couple hours after the 20 minute cure.

And this morning we mounted up the components after we cleaned up all the fasteners on the wire wheel in the drill press. For our first parts for the F1 rig out of the HotCoat system I have to say I’m really impressed. Mike is blown away with the quality and swears he will never ever paint another metal component again. He’s already ordered some high-temp powder so he can shoot our exhaust and some low-temp powder so he can shoot our aluminum structural components.

If you were able to handle using the EZ-Bake oven when you were five years old and turn out those little cornbread muffins, you could easily turn out professional grade powdercoated parts in about three hours from ‘unbolt’ to ‘bolt it back on’ with a little practice. Now if you could only powdercoat fiberglass.

~Sarah