Well kiddies… it’s nearly time for Sarah and I to head to Road America. And the difference between the tracks that Sarah and I normally race on and Road America is straights and sweepers that you could land a 747 on. Fellow sidecar brethren and two-wheeled racers who have run there warn us of massive roller-coaster elevation changes, seemingly endless and wide pavement that has you pinning the throttle for what feels like days, and extremely high speed sweepers that make the top of the backside of 9 laughable.

The CSR is geared pretty short for most the tracks we run at, more grunt on the bottom end to haul my fat ass around, and get Sarah the holeshot advantage she likes to use off of the corners when she makes passes. But Road America is a different beast, a lazy blubbery object curled up in a fetal position clinging onto the back of a F1 sidecar platform in motion, tends to stay in motion.

With that in mind, I bought a new 46 tooth chain ring, a 42 tooth chain ring, and a 15, 16, and 17 tooth counter shaft sprocket.

First… Let me teach you how to do some basic math to figure out just how fast your bike will mechanically go, not counting for wind resistance or rolling resistance.

…,

1 ~ Whip out your best thin tape measure, and accurately measure in cm around the circumference of your tire. Not all tires are the same size, and tires do wear over time. So if you want to know how fast you can go -right now- take a measurement right now. In my case, 164cm on the Yokohama slick on the back of the CSR, or 1640mm.

1a ~ Convert that to Kilometers, or in other words, add a dot and two zeros. 0.00164km. Save that number, it’s important later.

2 ~ Pick a RPM, for the sake of sanity, I chose 11,000 ~ Sarah’s shift light is set to 11,500 RPM. Multiply that times 60, you get 660000 Revs Per Hour.

3 ~ Find out what your Primary Drive Ratio is, it’s in your manual, online, mine is 1.604

4 ~ Find out what your 6th gear ratio is. Mine is 29 teeth to 25 teeth or, divide 29 by 25 and you get a 1.16 ratio

5 ~ Now for some math…

Revs Per Hour 660000 divided by the primary drive ratio of 1.604 equals 411471 Revs Per Hour primary drive ~ divide that by the 6th gear ratio 1.16 equals 354716 Revs Per Hour of the counter shaft.

6 ~ Now you figure out the possible combinations of final gearing ratios you want to choose from by simple division.

6a – Final Ratio ~ counter shaft sprocket 15 / rear sprocket 42 – 2.8

6b – Final Ratio ~ counter shaft sprocket 16/ rear sprocket 42 – 2.625

6c – Final Ratio ~ counter shaft sprocket 17/ rear sprocket 42 – 2.47

6d – Final Ratio ~ counter shaft sprocket 15/ rear sprocket 46 – 3.07

6e – Final Ratio ~ counter shaft sprocket 16/ rear sprocket 46 – 2.875

6f – Final Ratio ~ counter shaft sprocket 17/ rear sprocket 46 – 2.71

7 ~ Now that you have your counter shaft to rear sprocket ratios divide your counter shaft revs per hour (354716 in my case) by your selected final ratio to figure out how many revolutions per hour of the rear wheel that particular gear ratio will give you.

7a 15/42 – 126684.2857 rph rear wheel

7b 16/42 – 135129.9047 rph rear wheel

7c 17/42 – 143609.7165 rph rear wheel

7d 15/46 – 115542.6710 rph rear wheel

7e 16/46 – 123379.4782 rph rear wheel

7f 17/46 – 130891.5129 rph rear wheel

8 ~ And once you have your Revs per Hour of the rear wheel, multiply that by your original measured KM tire circumference. In my case 0.00164km. Then convert the Kph to Mph and you’re set, you have your theoretical top speed at that given RPM (11k in my case) for that gear ratio.

8a 15/42 ~ 207.76 kph ~ 129.10 mph @ 11k RPM

8b 16/42 ~ 221.61 kph ~ 137.71 mph @ 11k RPM

8c 17/42 ~ 235.51 kph ~ 146.35 mph @ 11k RPM

8d 15/46 ~ 189.48 kph ~ 117.74 mph @ 11k RPM

8e 16/46 ~ 202.34 kph ~ 125.73 mph @ 11k RPM

8f 17/46 ~ 214.66 kph ~ 133.39 mph @ 11k RPM

…,

There are some tools that can do all this for you online with the flick of a few keys, but it’s nice to know the math to be able to do it yourself. And I like figuring things out. In my case I have an oddball rear tire size so calibration and measurement can’t be done by the preset online calculators.

Now that I had my gearing, I decided to gear as tall as I could go. 17/42 @ 146.35 at 11k RPM or hitting 160 at what I have the rev-limiter set in the translogic unit.

So I got the new gearing installed, and a new chain on. But now I needed to recalibrate the speedo, which has always been off to begin with due to the 13 inch rim on the back and oddball sprockets. For this we’ll be using a product called the “Speedo Healer”

I got in on a group buy on this two years ago, and it’s literally been sitting on my shelf ever since.

But, how do you calibrate the speedo on a stationary vehicle?

Well, the -lazy- way is to go down to the local bike shop and buy a Cateye Enduro 8 MTB speedometer for 30 bucks.

This unit allows you to enter in the circumference of your wheel (164cm) and then has a wired lead to a hall sensor that picks up the pulses from a magnet that you mount to a rotor/sprocket/etc on your wheel.

For my purposes I simply drilled and tapped one of my sprocket bolts for the magnet carrier, and secured it in place with a little epoxy just to be sure. I then just used the stock components from the kit to zip-tie the hall sensor to the swingarm in close proximity to the magnet.

Once I had the bike in gear and running, the CatEye speedo picked up changes in speed accurate down to the 0.5 intervals. I was pretty impressed.

The Speedo-Healer has a steep learning curve in terms of calibration. The directions flat out suck. They’re written by someone who has a fetish for complexity and verbosity where it is not needed. I think I found Fenor’s afterhours gig. If the guys from Speedo-Healer are reading this, please contact me, I could write clear and concise directions for this unit that fit on a matchbook cover, not the three page mess that you deliver with the product.

Needless to say it’s thankful I can count binary on one hand that I’m good with dip switch configuration hardware. Only the last three switches, 4/5/6 really matter for speedo correction, and 3 decides if your doing positive or negative adjustment. 4/5/6 equates to Ones/Tens/Hundredths of increment of adjustment in nine step adjustment intervals as determined by a pulse sequence from the LED embedded in the unit. (Think cheap ODB-II code reader) The toughest part of the whole thing once you have the swing of it is remembering that (in my case since I was correcting the speedo down) to set the speed higher you have to add less to your 4/5/6 settings because the unit is set to correct down. My magic number was 1 pulse on 4, 7 pulses on 5, and no pulses on 6. Flipping all the dip switches down once you’ve got it configured writes the settings to NVRAM, and you’re done.

I was able to throw the CSR into 6th gear and go up and down steady through the rev range and watch the stock speedo and CatEye Enduro 8 stay in exact synch with each other. The Speedo-Healer while having a clunky interface does as advertised.

The major drawback to this is of course since the pulse width modulation coming from the transmission pickup was now being changed by the Speedo-Healer my Endgear digital gear indicator was now out of wack. But luckly the Starlane unit is easy to recalibrate and takes all of 30 seconds to get back in sync with the transmission. It’s just annoying to know that I’m going to have to do that every time we change our gearing ratios.

“But Mike? How do you know you made the right gearing choice for Road America?”

Well see, I think computers are amazingly useful tools, not only for talking shit on the internet, but simulating things you do not have the resources to do in the real world. And thanks to our sponsor SimBin we’re able to do just that.

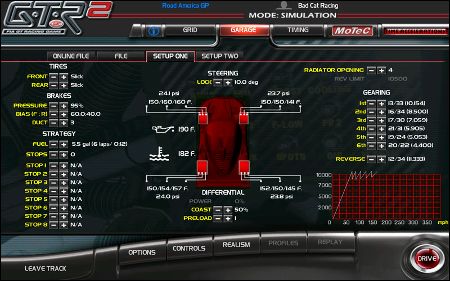

I fire up SimBin provided/modded copy of GTR2 and load up the Road America track expansion. I then load up the Radical SR3 with the 205 horsepower ‘Hayabusa’ powerplant that has been modified to have an asymmetrical chassis geometry to give it handling more in tune with a F1 sidecar.

I then plug in the first through sixth gear ratios from the 2004 CBR1000RR engine in our CSR, and start trying my available final drive ratios ‘in the simulator’ till I find a good combination of corner gearing and straight-line gearing. I set the redline on the motor to 11.5k and hit the track.

And then of course, I take it out on the track for a drive and see what it will do.