If you read my race-report about our Willow Springs weekend, you’d see that we had an issue with the 3 cent allen bolt that holds the translogic shifter in place snapping mid-race causing Sarah to lose most of her ability to downshift. This is the second time this has happened, just this time it happened at the heim joint at the top of the shifter servo as opposed to the heim joint at the bottom of the shifter servo.

The old design. Two inexpensive bearings press-fit into a sleeve with two allen bolts in single-shear. The allen bolt on the black heim joint is what failed last season in practice at Reno/Fernley.

The old top mount for the shifter servo, also single shear. The allen bolt is what failed during the race last Sunday.

First, engineering a new stronger bellcrank.

I decided to use thicker wall tubing and sealed roller bearings with retainer rings this time around. For the heim joints I decided to make my own clevis ends and weld them directly to the pipe so the heim joints would be supported from both sides.

Test assembly for clearance and movement was promising, and I would press-fit a bronze bushing into the internal race of the bearings to sleeve it down to the correct size for the bolt the bellcrank mounts on.

And of course, once I had the parts finished, everything had to be powdercoated. Instead of using bolts, I made steel pins which are drilled at either end. I will safety wire these just like you would safety wire a brake caliper pin. A solid pin ensures no slop in the heim joints and no worry of failure due to breakage.

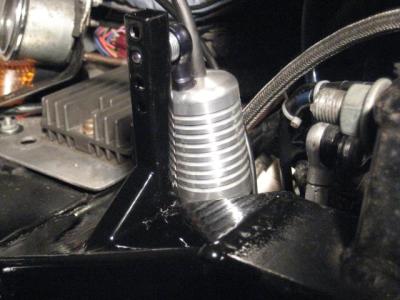

once installed, it was on to the top end of the mount. Essentially there it was the same type of redesign, just slightly modified. I gas-braised together two lengths of square tube stock, then created a clevis in one of the tubes. I then drilled through both tubes to allow for the placement of a securing pin, clamped the new clevis to the existing mount, and gas-braised it in place, cutting off the excess after it had cooled down.

I fabricated a similar pin for the top mount which will get safety wired as well.

So much for that, I don’t expect we will be having any issues or failures with this subsystem any longer.

-Mike-